What to Consider when Deciding on a Vertical Bifold Wallet

What are the most important factors to you in deciding which wallet to buy? Design? Durability? Price?

This buying guide will you give in-depth information about wallet quality. After you read it, you’ll be able to tell the different grades of leather, examine a wallet’s craftsmanship, judge its layout and design, and have an idea of what different wallets are worth. You’ll also have a better understanding of some tricky marketing terms and how to read between the lines of a warranty.

We’ll start with what the wallet is made of and then discuss the features and designs of various vertical bifold wallets.

Materials

The best indicator of how long a vertical bifold wallet will last is the primary material it’s made of. And the range is huge. On the low end, a wallet might only last 1 year. On the high end, it could last 100 years.

Let’s look at the different grades of leather first, and then, we’ll discuss some leather alternatives and the various secondary materials that a wallet will or might have included in its construction.

Leather Quality

How many grades of leather can you name? Most people have only heard of genuine leather and bonded leather. They’re the most common grades sold in department stores. They’re also junk.

To explain why, let me briefly go over the basics. Leather is made from animal hide. It’s skin. And the hide has different layers of skin. Not all layers have the same qualities. You know that if you cut yourself, the lower layers of your skin aren’t as hard as the top. As your cut heals, the skin grows up from the bottom, and that lower layer of skin hardens as it becomes the top layer.

It’s the same with animal hide. The bottom layers aren’t as tough, strong, resilient, or tight as the top layers. And it’s those bottom layers that genuine and bonded leather is made from. In fact, bonded leather isn’t even whole pieces of hide. It’s scraps of genuine leather leftover from another project. They call it “bonded” because the scraps have been bonded (glued) back together and pressed into a sheet. That sounds like a durable material, doesn’t it?

To better understand what the bottom layers of a hide actually are, consider that suede and leather shoestrings are made of the same material. Suede is a nice material, but it’s not very durable. It’s not something you would make a wallet out of. And leather shoestrings can be stylish, but I wouldn’t want a wallet made out of them.

But genuine and bonded leather isn’t just the bottom layers of a hide. To make the material stiffer and more durable, manufacturers add polyurethane to the top of the material. It creates a nice finish that looks like leather.

So, the polyurethane finish makes genuine and bonded leather okay, right? Wrong. Whereas it does add durability, it only does so for a limited time. Within a couple of years, that polyurethane will dry out, crack, and peel. The attractive finish will be ruined, and the soft leather underneath will be exposed.

The only advantages of genuine and bonded leather are that they’re cheap and easy to work with. The disadvantage is that it’s cheap in every negative connotation of the word. It doesn’t last and probably isn’t worth what you pay for it.

So, if genuine and bonded leather is out, what’s in?

The highest grades of leather of are full-grain and top-grain. And just like bonded leather is a form of genuine leather, so top-grain is a form of full-grain. They’re made from the top layers of hide and so have all the resiliency, tightness, and durability leather should have.

When top-layer leather is called full-grain, the natural grain of the skin of the animal has been preserved. You’ll see its pore pattern, the creases in its skin, its birthmarks, branding marks, scars, and mosquito bites. People like full-grain because it’s rustic and every piece of leather is unique.

For those who don’t appreciate the rustic, unfinished look, manufacturers produce top-grain leather. They sand the full-grain leather down until it doesn’t show any of the natural markings. Depending on the look they’re going for, they can emboss an artificial pore pattern back into the leather or leave it smooth. If they do emboss a pattern into it, it will be uniform, not like the varied texture of full-grain.

The advantages of full-grain and top-grain leather are how durable they are how tight they are. A piece of top-layer leather can last more than 100 years with very little stretching. The disadvantage is that it is more expensive and takes more skill to work with. But even though it lasts 50 times as long as genuine and bonded leather, it only costs 3-5 times as much. We’ll discuss pricing at the end of the buying guide after we’ve covered all of the factors.

There is one more grade of “leather” to consider before we move on, and that’s fake leather. You’ll see it referred to as koskin, vegan, or faux leather. You don’t want it.

It has the same durability as genuine and bonded leather because it’s also coated in polyurethane. The material underneath (nylon, polyester, or cotton) might or might not be more durable than bottom-layer leather, but the polyurethane topcoat still won’t last. A fake leather wallet shows cracking and peeling within 2 years of purchase.

Now you know what the different grades of leather mean. But what if you’re reading a product description and it doesn’t mention what grade of leather the vertical bifold wallet is made of?

That’s a sure sign that the company doesn’t want to tell what grade they used. If they used the durable top-layer leather (full or top-grain), they’d be happy to tell you. If they used fake leather, they’d be happy to say so and market toward vegetarians and vegans. But if they used bottom-layer leather (genuine or bonded), they wouldn’t want to admit it for fear that you might actually know what genuine and bonded leather is worth.

If a product description doesn’t say what grade of leather they used, assume they used the worst.

Leather Tanning

Did your dad ever threaten to “tan your hide”? He probably meant he was going to spank you and make your bottom turn red. He couldn’t have tanned your hide, though, unless he changed the molecular structure of your skin.

Tanning is the chemical process of transforming a hide into leather. The earliest form of tanning was spreading brain jelly on the hide. Thankfully, no major manufacturers use brain-tanning. They’ll either use vegetable-tanning or chrome-tanning.

Vegetable-tanning is accomplished with plant-based tannins. It’s a centuries-old proven method for tanning, but it takes almost a full day to do. The result is leather that stains easily in water. If it soaks up any liquid, it will show dark watermarks that never go away.

Chrome-tanned leather has been treated with chromium. It’s the same material sutures are soaked in to make them last longer in a person’s body after surgery. Tanning with chromium takes half as long as vegetable-tanning and doesn’t stain as easily.

You want to keep all leather from getting wet, but if you want a little more protection against liquids, choose chrome-tanned leather.

Leather Thickness

We’ve covered the grades of leather and a little about the tanning process. Now, we need to talk about the cut of the leather. We said that the highest-quality leather comes from the top layers and the lowest from the bottom. But manufacturers also have to thin the top and bottom layers to make a material they can shape. If they used the entire hide, it would be too thick to fold or put in your pocket.

So, manufacturers have control over how thick the leather is. If they want to make a more durable product, they cut it thicker. If they want to save money and make their leather supply go as far as possible, they cut it thinner.

If you’re looking at a wallet, each layer should be approximately as thick as a quarter. If you stand on it up, the material should be thick enough to hold its own weight without drooping or collapsing.

Even if a wallet has thick layers, though, it might not be made of thick leather. Try pinching the layers to feel if there are any inserts behind the lining. If you feel cardstock or plastic, the manufacturer reinforced the thin leather with the added material. Unfortunately, the inserts don’t make the wallet any more durable. In fact, they make the thin leather wear faster as the hard inserts rub and press against the back of the layer.

Thankfully, it’s usually only genuine and bonded leather wallet makers who use thin leather in their products. Those who use full and top-grain have an interest in making durable wallets, so they usually won’t undercut the quality of their leather by slicing it too thin.

Leather Scent

You can also tell the quality of a wallet by how it smells. Genuine, bonded, or fake leather that’s covered in polyurethane will smell like polyurethane. A vertical bifold wallet that’s made of full or top-grain leather doesn’t need a polyurethane topcoat, so it will smell like leather.

What if the wallet doesn’t smell like anything?

The scent of real leather doesn’t go away. The scent of chemicals can dissipate. If it doesn’t smell like anything, the polyurethane odor has faded, but the coating still won’t allow the scent of leather to escape. A wallet with the polyurethane cracking and peeling will actually smell better than it was new because the shell has cracked, allowing you to smell the leather underneath.

Leather Feel

You can also judge the quality of leather by how it feels. Bottom-layer or fake leather coated with polyurethane feels like plastic. Even top-grain leather with a smooth surface has the natural feel of leather. If the wallet feels artificial or has a very shiny appearance, bet that it’s not top-layer leather.

Leather Quality Summary

Full and top-grain are the best, lasting 100 years or more. Everything else is covered in polyurethane and only lasts a couple of years. Choose full-grain leather for an authentic, rustic look. Choose top-grain for a more fashionable finish. Both will smell and feel like leather. If you have a choice between chrome-tanned and vegetable-tanned leather, choose chrome-tanned for less water staining. Whichever you, make sure that the cut is thick enough to support its natural durability.

Nylon

We don’t like wallets that feel like plastic when they’re coated in polyurethane. Plastic that feels like plastic because it is plastic might be a different matter.

Nylon is a soft, flexible, durable thermoplastic. You can find any type of wallet, including vertical bifold wallets, made from nylon. Such wallets are thin and sporty. You can also get them wet, and they won’t stain.

The look of nylon isn’t as classic as leather, though, so unless you’re a very casual kind of fellow, you might only want to keep a nylon wallet for certain occasions. Use a leather wallet for everyday use, but if you go out to jog, play sports, or splash around in the water, transfer the essentials to your nylon wallet so that you don’t have to worry about ruining your leather one.

Nylon is inexpensive, so a nylon wallet won’t cost you much more than a wallet made of genuine or bonded leather.

Polycarbonate

There are also many vertical bifold wallets made of polycarbonate. Polycarbonate is also a thermoplastic, but unlike nylon, it isn’t very flexible. It’s good for making shell-type wallets. They’re durable, but don’t feel very comfortable in your pocket.

They’re also much less expensive than full or top-grain leather wallets, so they might make a good alternative for some men. Older tend to think that polycarbonate wallets look too trendy to use.

Construction

Full and top-grain leather, nylon, polycarbonate: all durable materials to make a wallet out of. But those materials need to be held together by stitching. The pockets might need a separate lining. ID windows, elastic bands, pull-tabs, money clips, snaps, chain rings, and zippers can all be added to enhance the functionality of a wallet. They can also ruin an otherwise durable wallet.

Let’s take a look at how to tell the difference between high-quality construction and cheap secondary materials.

Stitching

If you’re considering a leather or nylon wallet, check the stitching pattern. You should see either two parallel lines of stitching along every edge or one line of stitching that crosses over itself. This double or cross-stitching pattern reinforces the threads when the wallet bends or pockets flex outward from holding cards and cash.

The stitching pattern itself is a matter of style. If you like a more subtle wallet, you’ll probably like the double-stitch pattern. If you like your wallet to be more decorative, you’ll appreciate cross-stitching. You might even find a cross-stitch with large or contrasting-colored threads to make the pattern stand out more.

If you follow the line of stitching to the end, you shouldn’t see any knots or loops. Instead, you should see that the ends of different lines of stitching have been melted together. Fusing the ends together helps ensure that the threads are continually pulled tight without the chance of coming loose or fraying.

You might also be able to tell what the threads are made of. Nylon and polyester are the most durable with cotton being the third, less durable option. Cotton stitching won’t fail under normal circumstances, though, as long as it’s double or cross-stitched.

Lining

Some leather and nylon wallets will also have pocket separate pocket lining if it isn’t the same as the primary material. Beware of cotton or silk linings. They can rip easily on the rough edges of a card. Better materials include pigskin, suede, polyester, and nylon.

Also, note the stitching pattern for the lining. Stitching should never cross the pocket. If it does, cards can snag the threads.

Clips, Snaps, Chain Rings, and Hinges

A leather or nylon wallet might include some sort of hardware. A polycarbonate wallet certainly will. If the vertical bifold wallet you’re considering has a money clip, test to see how many bills it can hold before the clip loosens. If it has a metal or plastic clip, move the hinge around to make sure it’s sturdy and securely attached to the wallet. If it has a magnetic clip, check that both the top and bottom of the clip are double-stitched to the wallet.

If it has snaps, test them a few times to make sure that the connections are tight. Pull on the snaps to see how well they’re fastened to the wallet.

Chain rings should have a wide lip around the leather or nylon with double-stitching in the material to make sure that it doesn’t come loose.

If the wallet closes on a hinge, test the action a few times to see that it’s secure and can open and close smoothly.

Plastic and Elastic

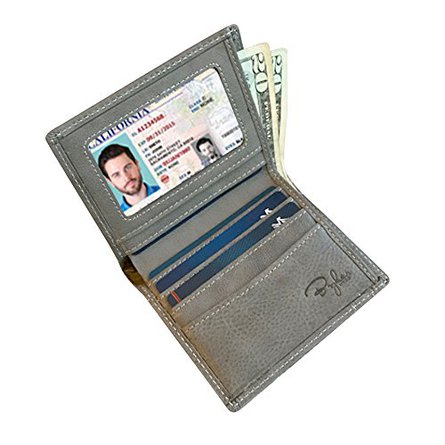

If you want to have an ID window included in your vertical bifold wallet, look for a wallet that has it on the inside. Exterior ID windows are more subject to being ripped, punctured, or dented.

If it has an elastic band for quick-access cards or cash, or an elastic pull-tab for a large, interior pocket, be aware that elastic stretches. It’s supposed to return to its normal tautness after you stretch it, but, after a while, it won’t. You’ll be left with a limp band that doesn’t hold anything. The pull-tab will take more pull, stretching the elastic even more.

Elastic can also fray and tear, strand by strand. When it does, that feature will be useful.

Zippers

A vertical bifold wallet made of leather or nylon might also have a zipper, either to close the entire wallet or to secure only one pocket, such as the cash pocket or a coin pouch. While not detrimental if it fails, look for a wallet with a quality zipper. It should take a little force to open and close, and it should close all the way to the end. There shouldn’t be any teeth spreading apart at the end when the zipper is closed.

The fabric around teeth of the zipper should be double-stitched to the wallet, ensuring that it can withstand the stress of repeatedly pulling on the zipper.

Construction Summary

The stitching should be reinforced with a parallel or cross pattern. The threads should be melted together at the ends to keep them tight and secure. The lining should not be made of cotton, silk, or any other material that be easily torn. Hardware should have little movement and be securely attached to the wallet. Plastic should be kept on the inside of the wallet and elastic should be used sparingly, if at all, for the sake of durability. Zippers should close tightly and be double-stitched to the wallet.

Craftsmanship

The last aspect you can check to determine a wallet’s quality and durability is the craftsmanship. This has to do less with the materials the wallet is made of and more how the wallet makers assembled those materials. You’ll want to examine the cuts and angles of the material, the uniformity of the stitching pattern, the finishing style of the pocket edges and wallet edges, and the sewing pattern at the wallet’s corners.

Cuts and Lines

When you look along the edge of each cut, you should it being perfectly straight. There’s no excuse for wavy lines. The angle of the edges and sewing pattern should also be straight. Check that each angle is parallel or perpendicular to the rest of the wallet. In a vertical bifold wallet, at least some of the card pockets should be perpendicular to the main fold.

Note that the corners should be rounded, not straight. Some angles might not be parallel or perpendicular, depending on the style of the wallet. In that case, the design will be obvious and should have a type of symmetry to the angles and lines.

The lines of stitching should look the same all the way around the wallet. You don’t want to see any gaps in the pattern or uneven sewing.

Pocket Edges

Manufacturers can finish a pocket in three ways. The simplest method is to simply cut the leather straight across the top. If the leather is thick enough, this finishing style makes a clean edge. If it’s too thin, the pocket will sag in the middle.

The second finishing style is to fold the leather over the top of the pocket and sew it to the inside. This has the advantage of making the pocket thicker. Just make sure that the folded material extends far enough down the pocket so as not to create a lip that cards can catch on. If your cards catch on the lip when you pull them out, you’ll not only get frustrated, but you’ll eventually pull the stitching for the fold loose, making the lip stick out more and eventually undoing the fold completely.

The third and most time-intensive finishing style is to roll the front of the pocket over. The material for the rollover needs to be thin enough to take the desired shape. When a wallet has thick pockets, the craftsman has to manually thin the top of the pocket to achieve this finish. If the wallet has thin pockets, a wallet maker will still need to take time to roll the pockets over, but the attractive finishing style doesn’t change the fact that the pocket is too thin.

Wallet Edges

A high-quality wallet also has thinned edges on the sides and bottom of the wallet’s perimeter. Thinning helps each layer of material blend together. When the sides aren’t blended, a vertical bifold wallet can look like a staircase with each layer of material for the pockets stacked on top of the next. Those thinned edges should be folded in so that you don’t see the edge of the leather.

A shortcut is coating the edges of the wallet with a resin. It gives the appearance of blended edges because you can’t see what’s under the resin. But do you remember what happens when you coat leather with polyurethane? The same happens with this type of resin. It dries out and peels away from the leather piece by piece. The result is a chewed-up edge that would have looked better without the resin.

Corners

The corners also need to be thinned so that they fold over toward the interior of the wallet. They should be folded into a rounded shape. Square corners wear faster as they catch and rub on the sides of the pockets in your clothing.

When the material is folded to make a rounded corner, the excess material will bunch up. Instead of cutting this away, it should be pleated and all sewn together onto the interior of the wallet. It will look like a curtain that’s bunched together when it’s open or like a closed accordion. Keeping the extra material sewn onto the interior makes a stronger corner.

Craftsmanship Summary

Lines should be straight or at 90-degree angles. Thick pockets can be cut straight across the top, folded over toward the inside, or rolled over toward the front. Folded pockets should not leave a lip for cards to catch on. The edges of the wallet should be thinned and turned inward with all layers blended together. Corners should be thinned, rounded, and sewn with a pleated pattern.

Warranty

The warranty that a company provides can confirm your inspection of the materials and craftsmanship. If a company sells a genuine leather wallet with a warranty of 6 months, for example, that should confirm that the manufacturer doesn’t think the wallet will last more than a year. They end the warranty early so that you can’t return the wallet in 9 months when the polyurethane cracks and the wallet finish starts to peel away.

A little trickier is the no-questions-asked money-back guarantee. Such a guarantee sounds reassuring. You know that you can return the product and get a full refund. But if you spend $15 on a genuine leather wallet, how likely is it that you’ll track down the company’s information, pay for the shipping to send it back to them, and wait to get your money back? The company knows that most people won’t bother. They get to sell you a low-quality product, knowing that only a small percentage of people will go through with seeing a refund.

On the high end of quality, you’ll see some companies offering 100-year warranties. The quality of these wallets is good, but who is going to take advantage of a 100-year warranty? You would have to keep your proof of purchase long enough to give it to your son or grandson and then they would have to consider if they want to get your used wallet repaired. It’s nice to have something from a loved one, but a wallet isn’t exactly a sentimental keepsake.

So, what is a reasonable amount of time for a warranty?

We’re comfortable with warranties that last 1-3 years. If you use your wallet every day for a year, you’ll discover any defects in its materials or craftsmanship. If you haven’t found any problems in that amount of time, you can agree that the wallet was well-made with high-quality materials. Any problems with a wallet after 1-3 years is a result of wear, not manufacturing shortcomings.

Size and Weight

How much should a vertical bifold wallet weigh? What are the average dimensions?

If you’re like us, you don’t want to fold your cash more than once. You also don’t want a wallet that’s too large not to fit comfortably in your front pocket. Keeping your wallet in front helps keep it safe and keeps your back from getting misaligned from sitting lopsided.

Look for a vertical bifold wallet that measures approximately 3.5” by 4.5”. With thick leather, it should weigh between 40 and 100 grams. That’s small enough to fit in your front pocket and light enough not to make your pants sag.

Capacity

A new vertical bifold wallet needs to have the capacity to carry everything you want to keep in your wallet. But before you judge the capacity of a model, take the opportunity to go through your wallet and weed out anything you don’t need. Maybe you could digitize some information on your cards. If you haven’t been to a store for a few months, you probably don’t need to keep their discount card in your wallet every day.

Once you have your everyday contents ready to go, try filling the wallet. The pockets in different models hold a different number of cards. The pockets of some are so tight that you can only fit 2 cards in them. Others allow for 3.

Keep in mind that pockets will also stretch a bit. If you buy a leather wallet that can only fit 2 cards in the pockets at first, try to fit a third card in the pockets after a month or two. The leather of each pocket will have stretched and relaxed a little from having the first 2 cards in them.

While you’re testing capacity, pay attention to the layout of the pockets. Will the pockets be easy to use? If you’re buying a vertical bifold wallet, how do you want the cash pocket to be oriented? Should it open at the top or to the side? Should all of the card pockets face the same way or do you want some to be horizontal and others to be vertical?

If you’re buying a high-quality wallet, it will be with you for quite a while, so make sure it will be convenient for you to use.

Features

A vertical bifold wallet can include a number of features. Keeping in mind the quality of secondary materials, what features do you find helpful? Do you like pull-tabs for large pockets? Do you like quick-access bands on the outside of the wallet? Do you want an ID window either on the inside or outside of the wallet? How about zippers or snaps? Would you like a coin pouch or key pocket? Do you use a wallet chain?

You’re buying a new wallet, an item that you’re going to use every day, so take the opportunity to think up what you want, and then browse until you find the model that best matches your ideal.

RFID Protection

While you’re brainstorming, don’t forget to include RFID protection. RFID stands for radio frequency identification. It’s the technology card readers use to scan your credit, bank, membership, and key cards. It’s used for IDs and passcards too. If you’ve ever held a card up to a door lock, you’ve seen how RFID works. A radio frequency reads the information on your card and then charges your account, confirms your identity, or verifies a code.

The problem is that you don’t need to voluntarily insert your card into a reader or hold it up to a door lock for your cards’ information to be accessible. If you’ve ever used an EZ passcard, you know that the information on the card can be read from a distance. It can also be read through most materials.

Someone with a remote scanner can access the information on your cards through your clothing and the wallet itself. The only material that blocks the scanning is metal. And you can buy a wallet with metal in it. Wallets that have RFID protection have a metallic mesh inserted in the lining of the pockets. Sometimes, they leave some pockets unprotected so that you can use your remote passcards if you want to. Others protect against the higher frequency, 13.56 MHz, to safeguard your financial and personal information while leaving the lower frequency, 125 kHz, passable for using key cards and passcards.

If you can’t find a vertical bifold wallet that you like that includes RFID protection, consider purchasing RFID blocking sleeves. You simply slide the sleeves over the cards you want to protect. They will add to the thickness of your cards, though, so you might not be able to fit as many cards in your wallet as you could without them.

Design

The design featured on the outside of the wallet is important. You’ll see it every time you take your wallet out of your pocket. So will everyone else. Do you want your wallet to make a fashion statement? Do you want it to clearly portray the logo of a popular brand? Or would you rather have a smooth surface with no imprints or company signatures?

Your wallet will hopefully be with you for many years, so think about whether you’ll still like the design for the life of the wallet. Your tastes could change, and brands go out of style. Many wallet makers adopt a subtle approach to appeal to a wide audience and to ensure that their designs never go out of style.

Purchase Options

Leather, nylon, and polycarbonate can all be dyed any color. If you find a vertical bifold wallet with high-quality materials and all the right features but hate the color, it’s not the right wallet for you. Look for one that comes in multiple colors that you can choose the best one for your style.

But, again, remember that you’re going to use your wallet every day for decades. Will you always enjoy the camo style or that neon blue and green wallet that you picked out? Color matters, but go for neutral tones to ensure the look doesn’t get old or outdated.

Packaging and Gift Boxes

When you’re ready to make your purchase (online), try to find out how it will be shipped to you. Does it come well-packaged in its own box? Is there a separate shipping box that the product box goes into to protect it in transit?

Does the company provide a gift box, and if so, what kind of gift box? Is the company referring to a plain box that you have to wrap or a decorative box that you can present without wrapping it?

Price

Taking all of the materials, craftsmanship, and features into account, how much should you pay for a vertical bifold wallet?

On the low end of pricing, a genuine, bonded, or fake leather wallet shouldn’t cost more than $15. The materials for such a wallet are inexpensive. Besides that, companies who use low-grade leather are also likely to cut corners on secondary materials and craftsmanship. They rely more on design and branding than actual quality.

Nylon and polycarbonate wallets could fairly cost $20-30. The materials are inexpensive, but they’re durable. You can buy a very well-made nylon or polycarbonate wallet either for everyday use or as a backup option for certain activities.

On the high end, a full-grain or top-grain leather vertical bifold wallet can appropriately cost $40-75. The material is relatively scarce, and it takes more time to work with. It’s also more durable than any of the alternatives.

As we mentioned, some wallets cost more than they’re actually worth based on branding. The company is marking up their product based on name recognition. If they have a reputation for quality or fashion, consumers will be more likely to buy from them. They can charge more because people recognize their brand.

But why not buy from the company you’ve never heard of? New companies start all the time, and if their products are just as high-quality as the recognized brand, their popularity shouldn’t be a factor. In many cases, less-known brands produce better quality than the industry leaders because the industry leaders place too much emphasis on their name and not enough on the quality of their products.

If you can get a lower price for the same quality, don’t worry about whose name is on the box. Examine the quality of the wallet and let the materials and craftsmanship speak for themselves.

Conclusion

Choosing a vertical bifold wallet can be difficult as it is sometimes hard to find quality options. Hopefully this article has helped you find one that will work out well for you. Just remember that it may be harder to find wallet accessories (wallet inserts) which will fit properly.

Which vertical wallet should you choose? The KEC Leathershop Vertic is the most authentic vertical design and has the added appeal of being hand-made with personalization options, but is made with third-tier leather at a premium price. The Bryker Hyde and Leatherology designs offer top-grade leather and more capacity for less cost. The Bellroy vertical wallet is a durable option with sufficient capacity at an affordable price. Finally, the Kinzd is the lowest price for third-tier leather and provides the most versatility.